Desktop fiber laser marking machine

Customer project: fiber-tuned Q laser

Project significance:The product is designed for anti-counterfeiting, traceability, and marking. It can engrave text, symbols and patterns, etc. on metal and some non-metallic materials. The character size can range from millimeters to microns to meet the desktop design needs. The product is low power consumption, flexible and compact, an cost-effective.

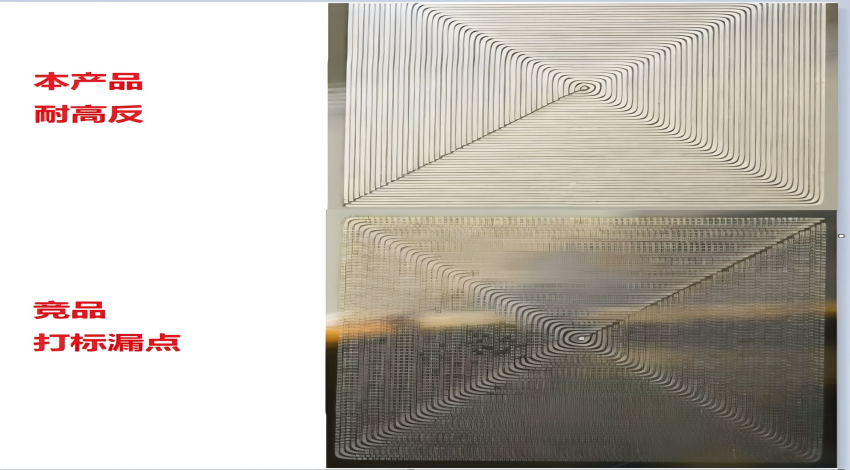

Related products: CJYDF-10/130, and 10/130 ytterbium- doped double cladding fiber.The fiber product has high environmental reliability and supports application in environments between -15 ~ 40 ℃. It has high anti-high reflection performance, high slope efficiency and adjustable pulse width.

.jpg)