LiDAR (Light Detection and Ranging) is generally composed of modules such as lasers, laser transmitters, laser receivers, and computer processing units. It uses pulsed laser as the signal source, compares it with the signal received by the laser receiver, and obtains desired information through computer processing of parameters such as phase, frequency, polarization, and amplitude. The laser light source is the core component of LiDAR, with a significant portion of LiDAR systems using 905nm semiconductor light sources. These light sources offer advantages such as lower cost, relative maturity, and smaller final product size. However, they suffer from weak anti-interference capabilities, short detection ranges, insufficient penetration through rain and fog, and most critically, the 905nm laser poses significant risks to eye safety.

In contrast to 905nm semiconductor lasers, 1550nm fiber lasers have emerged as one of the key technical solutions for future LiDAR applications in autonomous driving, vehicle safety warning, distance measurement, wind detection, and other fields due to their superior beam quality, high peak power, long detection range, and eye safety.

Wuhan Changjin Laser Technology Co., Ltd. (hereinafter referred to as "Changjin Laser"), based on 20 years of deep expertise in special optical fibers, has specially developed a series of optical fibers for 1550nm fiber-optic LiDAR, including erbium-doped single-mode fibers, erbium-ytterbium co-doped fibers, and erbium-ytterbium co-doped polarization-maintaining fibers. Notably, erbium-ytterbium co-doped polarization-maintaining fibers for LiDAR are currently subject to import restrictions. As the first domestic enterprise to launch erbium-ytterbium co-doped polarization-maintaining fibers, Changjin Laser aims to break through foreign blockades and escort the rapid development of China's LiDAR industry. It is reported that the specifications of these fibers meet the standards of imported counterparts, with some parameters exceeding those of imported products. Since their launch, the products have gained wide recognition from customers.

The Applications of LiDAR

Laser ranging

Laser ranging typically uses pulsed lasers as the light source. 1550nm pulsed lasers have become an ideal light source for laser ranging due to their advantages such as small laser divergence angle, high pulse energy, and eye safety. The basic principle of pulsed laser ranging is that the laser emits a laser pulse, which is reflected back after hitting an obstacle and received and processed by the receiving system. The distance to the target can be calculated by the time difference between the emitted signal and the reflected signal. Laser ranging is widely used in power, construction, geology, fire protection, railways, agriculture, forestry, military and other fields.

1550nm fiber lasers have advantages such as small size, high conversion efficiency, and good beam quality. The commonly used gain media are erbium-doped fibers and erbium-ytterbium co-doped fibers. The first-stage pre-amplification is performed using a 980nm pump and single-mode erbium-doped fiber, while the second-stage amplification is completed using a 940nm pump and double-clad erbium-ytterbium co-doped fiber, as shown in Figure 1.

Figure 1. Schematic diagram of the 1550nm pulsed fiber laser principle

Vehicle-mounted LiDAR

In recent years, the concept of autonomous driving has been increasingly mentioned, and advanced driver-assistance systems (ADAS) have been developing rapidly. Vehicle-mounted LiDAR is regarded as an essential sensor for L3 and higher-level autonomous driving. It primarily determines the distance to obstacles by measuring the time-of-flight of laser signals, while also using laser beams to measure the relative distance between the object contours of obstacles and the vehicle. These data are then used to create high-precision 3D maps of the surrounding environment, ensuring the safety of driverless vehicles.

Figure 2. Applications of Vehicle-mounted LiDAR

Currently, LiDAR manufacturers mainly use laser emitters with wavelengths of 905nm and 1550nm. Light at a wavelength of 1550nm is less likely to transmit through the human eye's fluids, meaning LiDAR using 1550nm lasers can operate at significantly higher power without causing retinal damage. Higher power enables longer detection ranges, while the longer wavelength facilitates better penetration through dust and haze. As a result, 1550nm LiDAR is increasingly becoming a critical technical solution for vehicle-mounted LiDAR. Although some industry professionals believe the cost of 1550nm lasers remains high, efforts to reduce the overall cost of 1550nm LiDAR through in-house R&D capabilities and supply chain optimization will enable the provision of cost-effective LiDAR products to customers.

Wind Detection LiDAR

With the country's increasing emphasis on the environment, wind power generation, as a new energy source, has gradually become a national strategic emerging industry, with continuous growth in wind power installed capacity. Relevant studies indicate that by around 2030, wind power generation will account for 26% of the total power generation. However, as an uncontrollable natural resource, how to make full use of wind resources has become particularly important. Due to the abundant wind resources in mountain tops and coastal areas, and the extremely large and heavy blades of wind turbines (weighing approximately 20 tons), the construction of wind turbines is quite challenging. Under extreme weather conditions, if the blades cannot be adjusted in real time according to wind direction, they may be damaged along with the turbine units, causing significant economic losses. By installing wind detection LiDAR to monitor wind direction in real time and adjust blade orientation promptly, the safe operation of wind turbines can be effectively ensured and power generation efficiency improved.

As a new type of mobile wind detection radar, coherent Doppler wind LiDAR has become the mainstream solution due to its advantages of high measurement accuracy, high spatio-temporal resolution, wide detection range, and fast response speed. Doppler wind LiDAR utilizes the optical Doppler effect to deduce wind speed distribution by measuring the Doppler frequency shift of echo signals from laser beams transmitted in the atmospheric environment. There are two detection methods for Doppler wind LiDAR: coherent detection and incoherent detection. Coherent detection measures the beat frequency signal between the returned optical signal and the transmitted laser signal, while incoherent detection measures the energy change between the returned signal and the transmitted laser signal. Coherent detection is less affected by the environment, has high sensitivity, and is easy to integrate with devices, making it widely used in commercial wind detection LiDAR systems.

1.5μm polarization-maintaining fiber lasers have become the most mature solution for coherent wind LiDAR light sources due to their advantages of eye safety and long detection range.

.png)

Figure 3. Schematic Diagram of 1550nm Wind Detection LiDAR Principle

As shown in the figure, the laser output from the seed laser is split into two beams by a polarization-maintaining (PM) beam splitter. One beam is modulated by an AOM (acousto-optic modulator), pre-amplified by an erbium-doped fiber amplifier (EDFA), and further amplified by an erbium-ytterbium co-doped fiber amplifier (EYDFA) to increase the pulse laser energy. The amplified beam then passes through a laser circulator and is focused by a telescope onto the target area. The focused laser beam scatters off atmospheric aerosol particles (where the laser wavelength is comparable to the particle size). A portion of the backscattered energy is collected by the telescope, coupled into the circulator, and directed to the detection system.

The other beam split by the PM beam splitter serves as the local oscillator (LO) light. It combines with the received signal light from the circulator in a single-mode PM coupler and enters a balanced detector for mixing. The mixed signal is filtered through a low-pass filter, amplified, and then acquired and stored by an analog-to-digital (ADC) card. Finally, the data is processed by a computer system.

All fibers and passive optical components in this system are polarization-maintaining to minimize noise caused by polarization mismatch between the backscattered signal and the LO light. This ensures maximum coherence efficiency between the signal and LO beams, enhances the system's signal-to-noise ratio (SNR), and enables precise wind measurements.

The Current Status of Erbium - Ytterbium Co - doped Fiber

Erbium-doped fiber (EDF) and erbium-ytterbium co-doped fiber (EYDF) are the core gain materials for 1550nm LiDAR light sources. Due to their extremely high manufacturing complexity, the core production technologies and processes have long been monopolized by foreign optical fiber enterprises. For a long time, domestic LiDAR companies have had to purchase erbium-ytterbium fibers from abroad at high prices for R&D and production, severely restricting the development of China's LiDAR industry. Particularly under the current international situation, the U.S. has been strengthening technological blockades against China, increasing the risk of complete decoupling between the two countries. Notably, the 25/300 polarization-maintaining erbium-ytterbium co-doped fiber, a critical gain material for wind LiDAR, has been restricted for export, making procurement increasingly difficult and potentially impossible in the future. This has left China's LiDAR industry heavily dependent on foreign suppliers, placing the entire industrial chain in a passive position.

After over two decades of technological accumulation and innovative R&D, Changjin Laser has successfully developed erbium-ytterbium co-doped fibers, polarization-maintaining erbium-doped fibers, and polarization-maintaining erbium-ytterbium co-doped fibers. The annual shipment of its 10/125 erbium-ytterbium co-doped fiber has reached 100 kilometers, with performance and consistency matching those of imported fibers, earning high customer satisfaction. In particular, the company has also developed the 25/300 series large-core polarization-maintaining erbium-ytterbium fibers, which were previously restricted for export by foreign countries. These fibers meet the specifications and performance of well-known international products and have received excellent customer feedback.

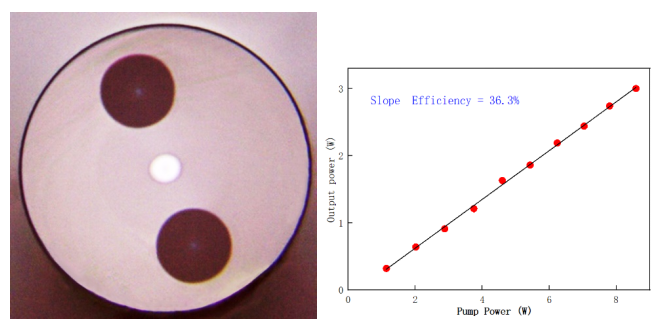

Changjin Laser's independently developed 6/125 erbium-doped fiber and 10/125 double-clad erbium-ytterbium co-doped fiber have been successfully applied in 1550nm pulsed fiber lasers. Figure 4 shows the cross-section (left) and slope efficiency (right) of the erbium-ytterbium co-doped fiber.

Figure 4. Fiber Cross-section (Left) and Slope Efficiency (Right) of Erbium-Ytterbium Co-doped Fiber

The cross-sectional view and slope efficiency of Changjin Laser's 10/128 erbium-ytterbium co-doped polarization-maintaining optical fiber are shown as follows:

Figure 5. Cross-sectional View and Opto-Optical Efficiency of 10/128 Polarization-Maintaining Erbium-Ytterbium Co-Doped Optical Fiber

Figure 6. Cross-sectional View and Slope Efficiency of 25/300 Erbium-Ytterbium Co-Doped Polarization-Maintaining Fiber

With the development of LiDAR technology, the applications of erbium-ytterbium co-doped fibers will become increasingly extensive. Changjin Laser is bound to follow market demands, continue to invest in erbium-ytterbium co-doped fibers, and provide strong technical support for the development of domestic industries such as LiDAR.